What Is a Filter Press and When Should You Rent One?

What Is a Filter Press?

A filter press is an essential piece of industrial equipment engineered to separate solids from liquids through a high-pressure filtration process. Its design enables operators to handle significant volumes of slurry or sludge, producing a solid filter cake and clear filtrate. For businesses looking for a flexible solution without the upfront investment of ownership, exploring a filter press rental Spring, TX can be a smart strategy. This provides the benefit of industry-leading technology and the convenience of on-demand access.

In recent years, filter presses have expanded their role in diverse industries due to their efficiency, reliability, and ease of operation. They are frequently used for wastewater treatment, mining operations, chemical manufacturing, food processing, etc. Renting a filter press enables organizations to adapt quickly to changing project requirements, minimize downtime, and maintain operational continuity.

How Does a Filter Press Work?

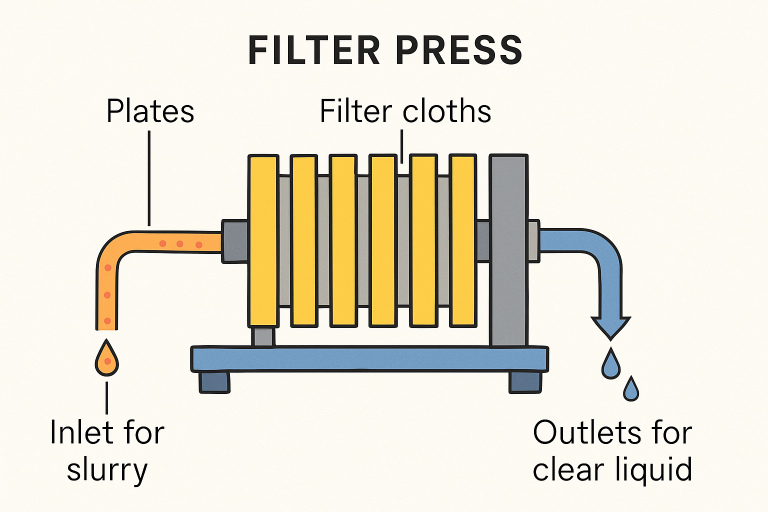

The operating principle of a filter press revolves around using pressure to force a slurry mixture through filter cloths arranged between plates. The process begins as slurry is pumped into the chambers between the plates. During filtration, water or other liquids pass through the fine pores of the cloth. While the solid particles are retained and accumulate as a filter cake. When filtration is complete, the plates are separated, and the cake is removed for safe disposal or further processing.

Filter presses come in many configurations, including manual, semi-automatic, and fully automatic models. The level of automation and capacity are selected based on a project’s specific needs, with more advanced models well-suited for continuous or high-volume operations. This flexibility ensures that whether your goal is to meet environmental regulations or optimize production. A filter press solution is available to match the requirement.

Common Applications of Filter Presses

- Mining and mineral processing, particularly for the management of tailings

- Municipal and industrial wastewater treatment plants

- Food and beverage operations needing clarification or byproduct recovery

- Chemical manufacturing processes require the separation of liquids and solids

- Construction and drilling projects to treat jobsite water or manage waste streams

According to the U.S. Environmental Protection Agency, effective filtration systems are vital for maintaining water quality in both municipal and industrial settings. Helping industries meet strict environmental standards and reduce their ecological impact.

Key Benefits of Renting a Filter Press

Renting a filter press rather than purchasing outright provides many benefits, particularly for companies working on temporary projects, pilot tests, or fluctuating production demands. The most significant advantages include reduced upfront capital investment, the flexibility to upscale or downscale quickly based on operational needs, and less concern for long-term maintenance or storage costs. Rental agreements typically include technical support and regular maintenance, ensuring optimal performance and reducing the risk of unexpected downtime.

Beyond cost savings, filter press rentals allow organizations to quickly implement new projects or respond to emergencies. Such as system failures or unexpected increases in waste volume. This rapid deployment capability is especially valuable for industries that must comply with evolving regulations or encounter seasonal activity variations.

When Should You Consider Renting a Filter Press?

- Short-term remediation or environmental cleanup projects

- Pilot studies or process development trials

- Unexpected system malfunctions or emergency solutions

- Temporary surges in wastewater or production volume

- Seasonal or one-off construction or agricultural jobs

Filter press rentals are particularly effective when project timelines are uncertain, work volumes are variable, or there is a need for compliance with temporary discharge permits. By bridging gaps in capacity or supporting trial initiatives, rentals allow for cost-effective and efficient project execution.

How to Choose the Right Filter Press for Your Project

Selecting the appropriate filter press involves analyzing several key factors. Start by evaluating the total volume of material to be processed and the nature of your slurry or sludge (including particle size, density, and chemical compatibility). The degree of dryness required for the final filter cake will also influence the choice of filter cloth and press design. Additionally, consider the available space, access to electrical power, and how much automation your process demands. Consulting with filtration specialists ensures that equipment specifications align with your specific operational and regulatory needs.

Also Check: How to Keep Trees Healthy Throughout the Year

Cost Considerations and Project Planning

Filter press rental costs can vary depending on several factors, including the unit’s capacity, rental duration, and project complexity. Typical pricing includes delivery, setup, operator training, and routine maintenance. Project managers should carefully estimate total material volumes, define the project’s time frame, and determine the required shifts or on-site labor. Comparing daily, weekly, and monthly rates helps ensure budgeting accuracy and maximizes the return on investment.

Additionally, advance planning and clear communication with the rental provider can streamline setup, minimize delays, and reduce unforeseen expenses.

Final Thoughts

Filter presses remain among the most effective solutions for separating solids from liquids across various industries. Renting a unit provides businesses flexibility, cost savings, and rapid access to high-performance equipment without the long-term financial commitment of ownership. Whether for short-term remediation, pilot projects, or unexpected surges in demand, rental options allow organizations to stay compliant, efficient, and adaptable. By carefully assessing project requirements and partnering with an experienced provider, companies can ensure that their filtration needs are met while maintaining operational continuity and environmental responsibility.